Building A Sustainable Packaging Design Process

The United Kingdom creates 23 million tons of waste each year, 30% of this figure consists of packages. Considering the fact that the UK recycles 39 percent of its waste, the number increases in other countries that have a lower recycling rate. Having the packaging process part of every product development turns it to an initial factor in sustainable design strategy.

Sustainable packaging refers to the packing process that aims to reduce the environmental impact of package waste and improve sustainability. While introducing its packaging scorecard in 2006, Wal-Mart defines sustainable packing based on the four “Rs”; Reduce, Reuse, Recycle and Rethink.

The last term “Rethink” leads us to the idea that sustainable packaging is an on-going process that requires research and development for new methods and tools that ensure greener packaging procedures.

While the four terms define the sustainable packaging straightforward, the implementation is challenging. Does it mean to replace a larger package with a smaller one? Does it mean to replace the packaging components with more eco-friendly materials? Sustainable packaging is part of the broader meaning of the design process and it functions intertwined with the other stages of the product design development.

In IKEA, flat packing is closely related with the self-assembly product design strategy. In the 1960s, IKEA started self-assembly in order to reduce the space required for transporting products. Flat packing contributes to reducing the storage, transportation costs and carbon emissions during transportation from the warehouses to retail stores (Guide to IKEA’s Sustainable Design Strategy part 1, part 2).

Tips for sustainable packaging design

In order to create sustainable packing, specific tips should be considered during the production process. The tips below do not ensure full sustainability, but helps in improving the sustainability score.

Evaluate the life-cycle of the package design

Evaluating the life-cycle of the packing process helps designers to understand more about the environmental impact of the package design and if it meets with sustainable packaging targets such as using the proper materials. Many tools allow designers to understand where their package design stands on the road of sustainability. These tools include the following:

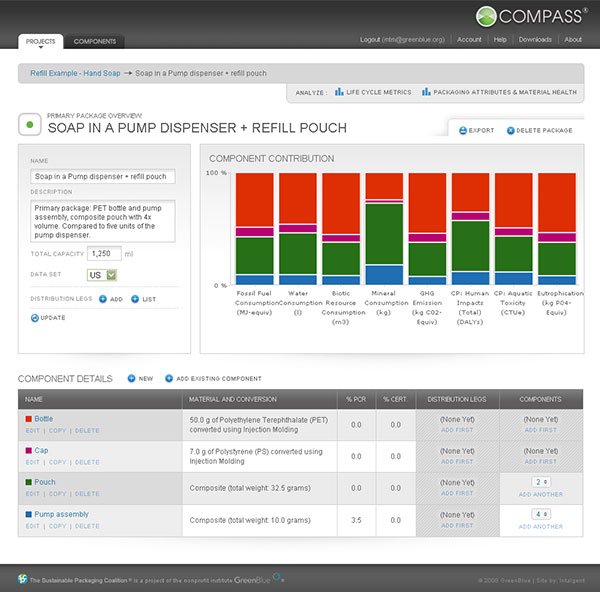

- Sustainable Packaging Coalition’s COMPASS (Comparative Packaging Assessment) online software

- PackageSmart LCA software from EarthShift

The tools above can be considered as evaluation methods for sustainable packing processes. While, the tools are still being developed, they can help in understanding the sustainability level of the product packaging.

Investigating packaging elements and sustainable alternatives

Many factors in packaging design should be evaluated in order to achieve sustainability such as the materials, weight of the package and volume. For example, Proctor & Gamble plans to replace 25% of the petroleum-based materials with renewable substitutions by 2020.

Additionally, new alternatives and modifications in the packaging process should be considered. For example, Unlimited Water Processing, Inc. replaced the corrugated cases to shrink-pack technology, which results in reduction of the packing cost from 4 cents to 10 cents. Also, the new packaging technology results in less materials and better look for the water bottles packaging.

The investigation for sustainable packaging should be aligned with innovation. The package can be used after consuming the product. This will help in reducing waste, as the consumers will use the package instead of throwing it in the garbage. For instance, Philips designed the package for their Active portable MP3 as a reusable bottle that can hold two liters of water, which is the amount of water recommended for a healthy human body.

Design sustainable products

As mentioned earlier, sustainable packaging is part of the New Product Development (NPD) process. Therefore, part of the sustainability plan is to design a product that ensures sustainable packaging. For example, product design should consider the final volume after packaging and the materials used in the packaging. For example, cleaning products are delivered in a concentrated format to reduce the volume and weight of the added water or liquid.

Consider the space-saving packages

In the IKEA example above, flat packing is one of the successful packaging systems that reduce the space required to store or transport the product, which subsequently reduces transporting costs and carbon emissions.

Sustainable packaging checklist

As mentioned, achieving a sustainable packaging goal is a challenging and complex process. In order to reach this goal, tools and procedures should be considered to ensure that the production process is moving forward to achieve this goal.

In addition to the tools mentioned above, a checklist should be asked during the production process to ensure the stages meet with sustainable packaging process expectations and requirements. These questions include the following:

- Is the package safe and healthy for consumers?

- Is the package reusable and beneficial?

- Ares the materials used in the package recyclable?

- Does the package depend on renewable source materials?

- Does the packaging process follow sustainable principles?

- Are the technologies used in production meeting with sustainability?

- Is the package designed to for minimal use of material, energy and space?

There is no doubt that packaging is an essential part of the production process either for new products or existing products. Therefore, it should be highly considered in any sustainable product strategies.

Sustainable packaging is an ongoing process and requires frequent evaluation and development in order to utilize new methods and tools for better output. While the tools we have so far are still developing, they can help designers to ensure better understanding to the package design process and if it meets with an adopted sustainable strategy.