Tracing the Open Design Practice

The term “open” is added to different fields such as design, innovation, and software in order to reflect co-creation principles with users contributing to the final design, either by assembling the product, customizing it, or adding more functions to it. A good example of open design is IKEA’s products that can be bought in separate parts that are flat-packed and are to be assembled by the consumers at their homes using the illustrated IKEA guide. In computer science, the term “open-source” means that the operating systems, software, and applications can be modified by the end user. The “open-source” movement was initially coined by Eric S. Raymond, Tim O’Reilly, and Larry Augustin in 1997. In 1999, Dr. Sepehr Kiani, Dr. Ryan Vallance, and Dr. Samir Nayfeh established the Open Design Foundation that aims to research further into open design.

While talking with my colleagues, our product designer, Adrian Peach, highlighted the Red and Blue chair that was designed in 1917 by Gerrit Reitveld (1888-1964) and used to reflect the De Stijl movement. While the chair design itself was not presented as an open design model, it had a simple design that was dependent on a wooden plane connected to each other with dowelled joints.

Earlier implementations of the open design principles can be traced to the 18th and 19th century. In his research, “Collective invention during the British Industrial Revolution: the case of the Cornish pumping engine” that was published by the Cambridge Journal of Economics, Alessandro Nuvolari highlighted collective invention settings as a crucial source of innovation during the early phases of industrialization.

Why Do We Need More Open Design?

Many modern trends have highlighted the importance of utilizing resources from outside companies in addition to internal resources, such as implementing open innovation and open business models. Shared benefits can be highlighted when utilizing open design in products and services:

- Improving creativity – the open design allows users to assemble or customize the product in a way that meets their needs in an often-innovative way. The collaboration between the in-house designers and consumers contributes to inspiring the team to make the product more user-friendly by observing the user experience while customizing and using the product.

- Lower cost – open design products avoid part of the production costs, such as assembly, large packing, and expensive transportation. These deducted expenses contribute to the reduced cost of the final product.

- Reliability – when consumers contribute to the product assembly or customization, they build more trust with the company because they can see the different parts and experience the quality of each element, unlike with closed design products where consumers don’t know the components of the final product.

- Flexibility and integration – open design products are much easier to customize and integrate with other elements in the space. For example, the open source furniture provided by IKEA are easier to customize based on the space and other elements in the room.

Open Product Designs

One of the most common open design product examples is IKEA’s self-assembly products. Consumers buy IKEA products as flat packed and assemble it using the famous IKEA illustrated guide. However, many initiatives tend to provide open design products where consumers can download the blueprints and documentation and start building the design themselves. The pod stool, which was designed by French designer Samuel Javelle, allows consumers to download the required documentations. They can cut the material themselves using a milling machine and assemble the final pieces using wooden screws.

Another open design product is the Never Ending Bench by designer Félix Lévêque. The product was introduced during the Fablab Squared in 2011, and it is made of wooden pieces that are placed side by side to expand the bench’s length. The documentation and blueprints of this product are available for download.

The Delight Lamp is an open design product introduced by the Open Design club for emergency flood control. The product is created using sandbags, and consumers can download the documentation and follow the PDF instructions to assemble it.

Another design is Ronen Kadushin’s Italic Shelf. Easy to produce and assemble, the system consists of only two parts of plywood shelves and spaces. The product can be easily built and customized using the documentation available on their website.

Open-Source Software

The open design is also known in the software industry as “open-source software.” There are two types of open-source software. One type is a full open-source where the product code is developed by a small team and given to the public to customize based on client requirements, such as the WordPress Content Management System (CMS). It is a platform to build blogs and websites where developers and designers need to download the framework and install to the website server, then it can be customized to create a wide range of websites. Another example of open-source software is the Firefox browser developed by Mozilla Foundation.

One of the most commonly known open-source operating systems is Linux, which is Unix-based. The operating system was developed by Linus Torvalds while he was attending the University of Helsinki. The operating system is distributed using the General Public License (GNU) where users can use, modify, and distribute. While the topic of depending on open-source software is still controversial for many, users depend on it because of its low cost, security, no vendor lock, and good quality.

3D Printing and Rapid Prototyping

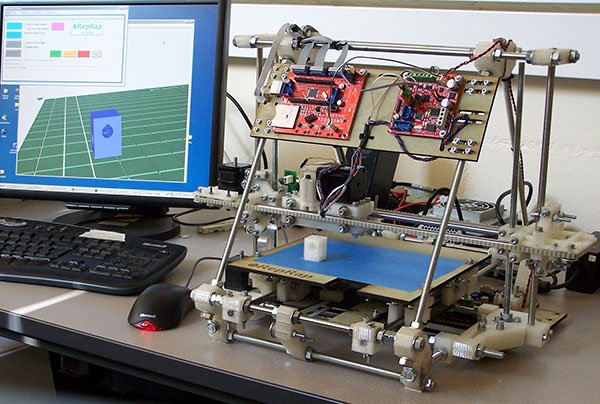

The rapid prototyping technology developed in the past decade has made 3D printers more and more affordable. Many manufacturers started to present affordable 3D printers that can be purchased for homes and small offices. These 3D printers have opened the doors for 3D printing application and implementations. The open design is applied in the 3D printing industry on two main levels: the open design of 3D printers and the open design for 3D printed products.

The Fused Filament Fabrication (FFF) is one commonly used technology in 3D printers. This method depends on ejecting the printer head for plastic filaments. The head is controlled by step motors that build the 3D object layer by layer. This technology makes it easier for many engineers to build their own 3D printers or sell 3D printers in separate parts that are assembled after shipping it to the consumer. RepRap 3D printers is an open design printer where designers and engineers can download the building instructions and buy the basic elements to start building their own 3D printers. The RepRap 3D printers are available on the GNU license and some parts can be 3D printed by other 3D printers.

The nature of the 3D printing industry supports open design principles, as consumers only need to have the 3D printer in order to download and print the product. This overcomes many of the obstacles of open design such as the lack of materials from the client side or lack of experience in assembling product elements. In my recent research in the Design Management Review, “Designing the 3D-Printed Prosthetic Hand,” one of the open design examples mentioned was the Enabling the Future project. This was started in 2011 as an open source initiation to help children with physical disabilities by offering them 3D printed prosthetic hands at an affordable cost. The initiation website includes all the necessary CAD files for building 3D prosthetic hands. Children and their parents from around the world can print the pieces using local 3D printers and assemble it to fit their children’s hands.

Conclusion

Along with the development of technology and the need to build a sustainable environment, open design can contribute to solving many of the obstacles that used to face the traditional closed design industry process. Although there are challenges faced by open design products, new technologies such as 3D printing can be utilized to overcome these obstacles and enable consumers to benefit from the advantages of an open design model, such as the low cost, flexibility and integrity.